Hydraulic braking system

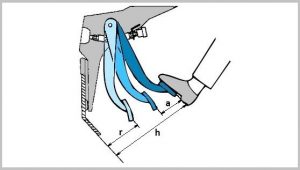

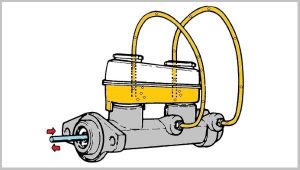

Most vehicles use a hydraulic braking system. Incompressible brake fluid is used to transmit the braking force. Pressing the brake pedal creates pressure in the hydraulic system, which is transmitted through the brake fluid through the lines and hoses to the braking unit.

The correctness of the vehicle brakes depends on the correctness of the hydraulic system. This system must always be ready to transmit the brake order to the end braking units.

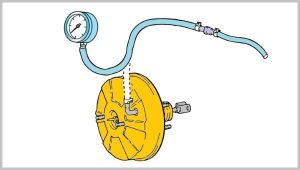

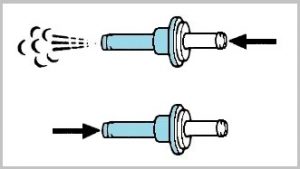

The hydraulic braking system requires periodic inspection and maintenance of the elements. When a malfunction is suspected, it is immediately checked, detected, and rectified. During the service, it is necessary to adhere to the manufacturer’s recommendations for a given vehicle in the knowledge of operating procedures and proper use of equipment and tools.